- Your cart is empty

- Continue Shopping

FILTRALITE

With Filtralite® filter media, made of lightweight expanded clay aggregates, you can do more with less – more pure water with less energy, less space and without rebuilding existing facilities. Filtralite ® Pure is a filter media suitable for both physical filtration and biological treatment.

Product Description

This media is made by heating clay to around 1200° C, followed by crushing and sieving. Dry particle densities in the range from 500 to 1.600 kg/m3 and aggregate size from 0 to 20 mm can be “tailor-made” for specific applications. In addition to its low density and high porosity, Filtralite® offers high abrasion and impact resistance.

With its unique porosity, Filtralite ® Pure filter media offers optimum conditions for water to flow through the filter bed in order to retain and adsorb more contaminants. This feature allows for larger volumes of water to be filtered through the same volume as contact area is increased. Water management facilities can thereby increase their output without having to rebuild and expand existing facilities simply by replacing the conventional filtering media with Filtralite ®. The product not only increase water output volumes, they also decrease operation costs. By replacing conventional sand filters with Filtralite ® Pure filter media, you can expect to get your money back in less than 3 years. Because Filtralite ® Pure filter media requires fewer backwashes, which means less energy and less water loss, which at the end of the day means more water out of your plant. This way, we ensure you get more out of the resources you already have.

Filtralite solutions can be implemented in mono media filters, as well as in in dual media solution (Filtralite Mono-Multi and Filtralite Mono-Multi Fine) in which two types of Filtralite Pure filter media with different densities and sizes are combined, improving even more filter runs and production capacity.

Filters with Filtralite can be operated within a large range of filtration rates. The filtration rate will always be dependent of the configuration of the filter and the treatment process.

Filtralite® as a biofilm carrier in fixed bed water treatment process:

Filtralite Pure is also excellent for treating, in fixed bed water treatment process, raw water containing ammonia, manganese, iron etc. Compared to other media, Filtralite has much higher porosity, which gives great specific area for biofilm growth, High number of macropores, Lighter density and High resistance to abrasion.

ADVANTAGES OF FILTRALITE® Pure single/dual media filter

Compared to traditional filter media, Filtralite ® has much higher porosity, which gives Lower initial head loss, Slower head loss build up, Higher particle storage capacity & Lower backwash rates.

These advantages result in much longer filter runs between backwashes, which means reduced energy and water consumption and higher water production, consequently giving reduced operating cost.

Filtralite ® Pure performance in numbers

In single media filters, time between backwashes can be extended by up to 500%

In dual media filters, up to 8 times less frequent backwashes

In biofilters, ammonia removal superior to 90%

Backwash rates lowered by 35%

ADVANTAGES OF FILTRALITE ® Pure in biological filters

Compared to other media, Filtralite ® has much higher porosity, which gives

- Great specific area for biofilm growth

- High number of macro-pores

- Lighter density than traditional media

- High resistance to abrasion.

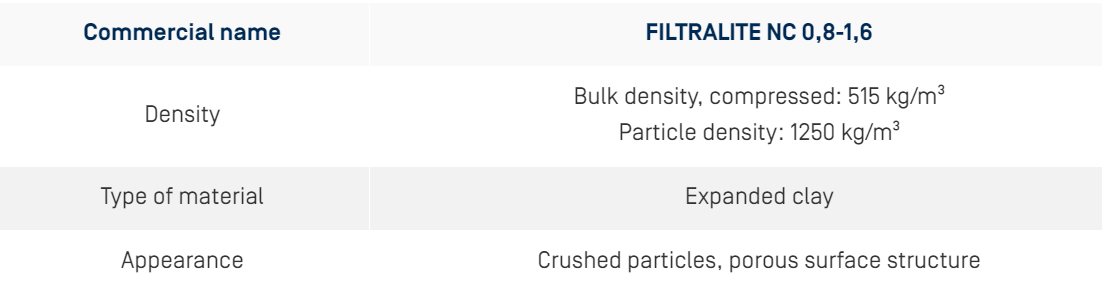

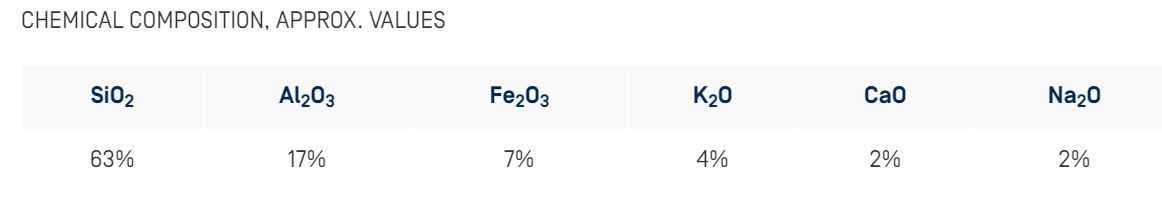

Filtralite® Pure NC 0,8-1,6

Description

Filtralite® Pure NC 0,8-1,6 is high quality filter media, manufactured from expanded clay material, used for filtration in drinking water treatment and pre-treatment for desalination.

Product

Crushed clay aggregates, normal low-density, 0,8-1,6 mm.

Advantages

Filtralite® media, with its highly porous structure, enables improved filter efficiency by longer filter runs between backwashes, which means reduced energy and water consumption and higher water production, consequently giving reduced operating costs.

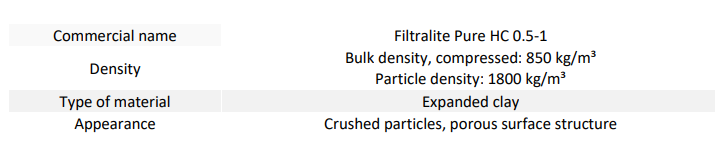

Filtralite® Pure HC 0.5-1

Filtralite® Pure HC 0.5-1 is high quality filter media, manufactured from expanded clay material, used for filtration in drinking water treatment and in Swimming Pool filters. The porous, sharp-edged grains have strong resistance against mechanical abrasion and low acid solubility. Filtralite® Pure HC 0,5-1 is an inert, ceramic material.

Product : Crushed clay aggregates, high density, 0.5-1 mm.

Advantages of Filtralite® Pure HC 0.5-1:

Filtralite® media, with its highly porous structure, enables improved filter efficiency by longer filter runs between backwashes, which means reduced energy and water consumption and higher water production, consequently giving reduced operating costs.

Application of Filtralite® Pure HC 0.5-1:

Filtralite® Pure HC 0.5-1 is used as filter media in conventional deep bed filters for particle removal. It can be utilized as single media filters in both open and closed filters for treatment of ground water, surface water and seawater, and in dual media filters.

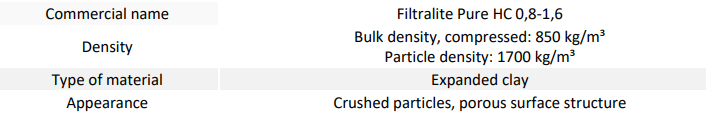

Filtralite® Pure HC 0.8-1.6

Filtralite® Pure HC 0,8-1,6 is high quality filter media, manufactured from expanded clay material, used for filtration in drinking water treatment and in swimming pool filters. The porous, sharp-edged grains have strong resistance against mechanical abrasion and low acid solubility. Filtralite® Pure HC 0.8-1.6 is an inert, ceramic material.

Product: Crushed clay aggregates, high density, 0,8-1,6 mm.

Advantages:

Filtralite® media, with its highly porous structure, enables improved filter efficiency by longer filter runs between backwashes, which means reduced energy and water consumption and higher water production, consequently giving reduced operating costs.