- Your cart is empty

- Continue Shopping

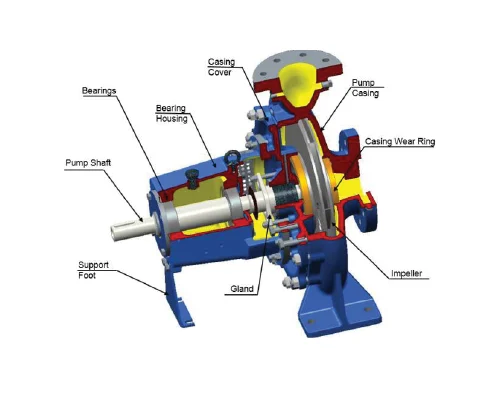

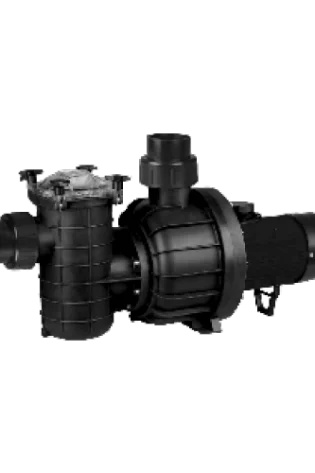

CENTRIFUGAL PUMPS- DBXe SERIES

FEATURES

Casing: The casing has axial suction and top centre line delivery with self venting design. Smooth hydraulic passage ensures highest efficiency. Delivery flanges and supporting feet are cast integral with the casing.

Impeller: The impellers are of enclosed type. Hydraulic balancing of impellers is achieved by balancing holes depending upon magnitude of axial thrust. The impellers are statically and dynamically balanced.

Shaft: The shaft is supported between antifriction ball bearings. The critical speed of shaft is sufficiently above the operating speed. The shaft is critically machined and ground to maintain concentricity. It is fully protected from the liquid being handled by means of shaft sleeve and ‘O’ ring and gasket between impeller screw & impeller.

Stuffing Box: The stuffing box is sealed by either gland packing or by mechanical seal.

Bearings: Pre-lubricated grease sealed bearings are used as a standard scope of supply. Pumps with oil-lubricated bearings will be supplied against specific order.

Direction of Rotation: Clockwise when viewed from driving end.

Drive: Pumps can be driven by electric motor or engine

Product Description

CUT SECTION

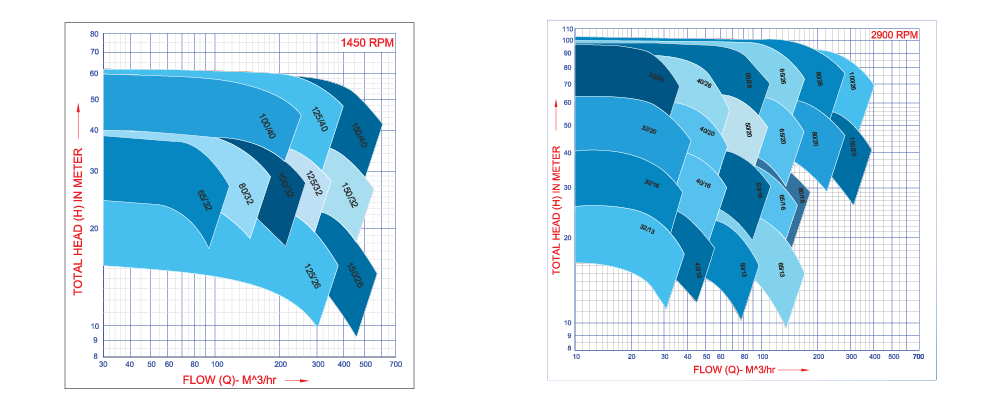

RANGE

Delivery size :32 to 150 mm | Capacity : Up to 550 m /hr | Head :Up to 100 meters

Speed : 1450 & 2900 rpm , 1760 & 3500 rpm | Working Pressure : 16 kg/cm (MAWP)

Temperature : -10 to 90 C

APPLICATIONS

DBXe pumps are mainly used for clean and clear liquids which are free from suspended solids/particles.

Few of the applications are as below.

- Water supply,

- Sprinkling

- Air conditioning

- Industrial water

- Swimming pool water

- Hot water (Up to 90 C)

- Fire fighting

- Drinking water/Potable water

- Cooling water

- Condensate

- Clear juice

CONSTRUCTIONAL FEATURES

- Dimensions are fully conforming to EN 733

- Centerline delivery with self-venting feature

- Back pullout type design

- Pump is having dry shaft design. (Shaft is completely protected).

- Max. allowable working pressure is 16 kg/cm2

- Flange drilling : BSEN1092 (DIN 2533 ND16) standard

Optional : ANSI class125FF, 150FF - Auxiliary tapping : BSP

- Coupling : Flexible jaw type spacer coupling

- Interchangeability of components

- High Energy Efficiency to comply to requirement of minimum efficiency

index MEI ≥0.7 for water pumps

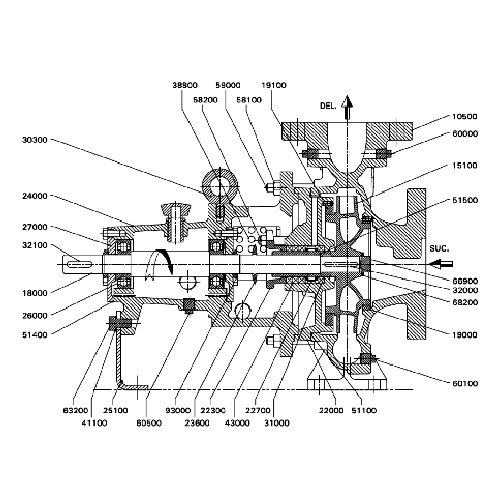

MATERIAL OF CONSTRUCTION

Pump Casing / Casing Cover : Cast Iron

Impeller : Cast Iron / Bronze / CF8M/ CF8

Wear Rings : Cast Iron / Bronze

Pump Shaft : CS 45C8 / St. Steel ASTMA-276 TYPE 410

Shaft Sleeve : St. Steel –ASTM A 276 Type 410 H

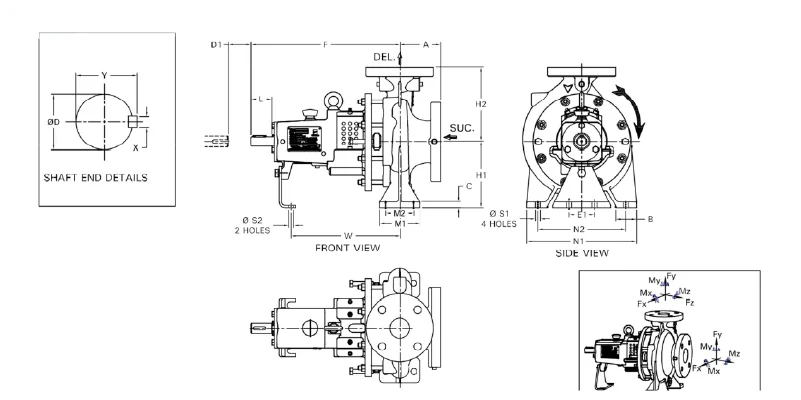

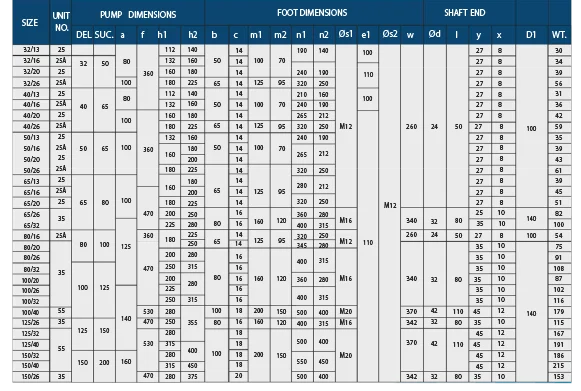

OUTLINE DRAWING OF VERSEAU PUMPS

D1- BACK PULL OUT DISTANCE REQUIRED BETWEEN MOTOR SHAFT END AND PUMP SHAFT.

NOTE- ALL DIMENSIONS ARE IN mm.

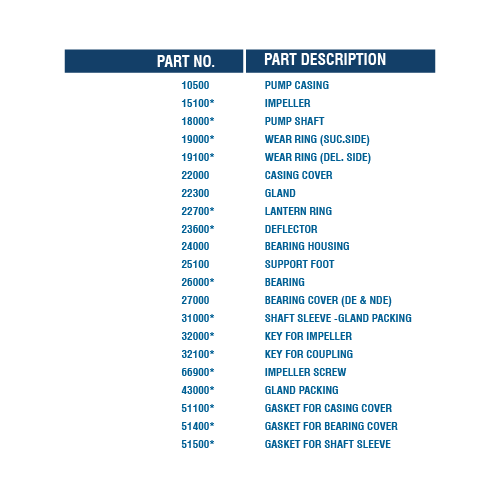

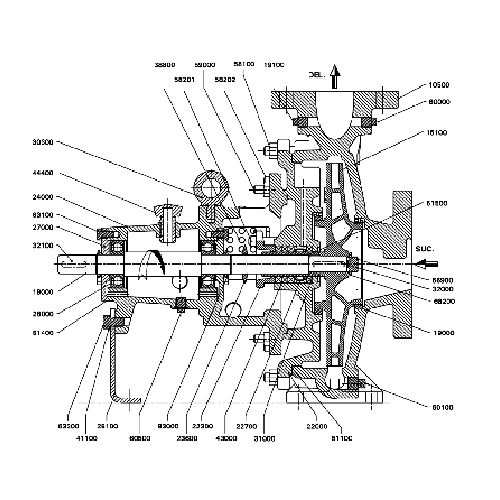

CROSS – SECTIONAL ASSEMBLY

DBXE 32/13 to 65/13, DBXE 32/16 to 80/16

DBXE 32/20 to 100/20, DBXE 32/26 to 125/26

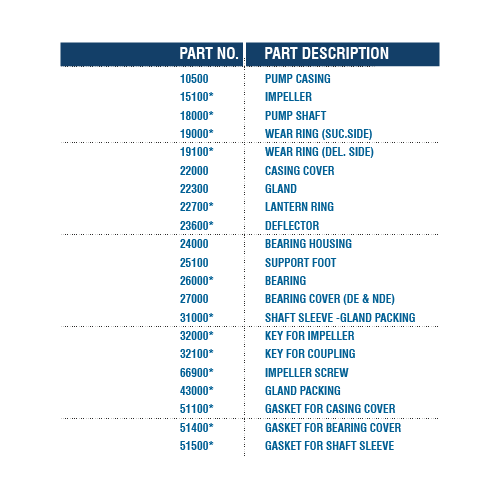

CROSS – SECTIONAL ASSEMBLY

DBXE 65/32 to 150/32 , DBXE 100/40 to 150/40

FAMILY CURVES